🔍 Unraveling the Enigma: Journey into the World of Electromagnetic/Magnetic Flowmeters 🔮

3D View of Accumax Instrument’s Electromagnetic Flowmeter

🌟 Are you intrigued by electromagnetic/magnetic flowmeters (EMF) and their applications? 🔗 You’re about to have a mind-blowing experience. To see an amazing 3D rendering of an electromagnetic flowmeter, click the link above. 🌪️🚀 Particularly in sectors where accuracy is crucial, these instruments are a dominant force in fluid monitoring. They have significantly changed the industry thanks to their remarkable precision, dependability, and low maintenance requirements. Join us as we explore their parts, operating principles, benefits, setup, upkeep, precision, uses, calibration, and advice on selection. Buckle up for an educational voyage into the intriguing world of flowmeters! 🌟

Introduction

These amazing instruments accurately gauge the flow rate of conductive substances including water, acids, and slurries. They have transformed sectors like water treatment, chemical processing, and beverages & food production. 🏭These flowmeters aren’t dependent on parts that move, as other measurement devices. 💡

Imagine a tool that reliably and accurately measures the fluid running via conduits (PS: We have something special for you! Go on scrolling, there’s an awesome film awaiting you later, just like you thought! 😉). That is the potency of electromagnetic/magnetic flowmeters! 💪They are the preferred choice for a variety of industries thanks to their cutting-edge technology and durable construction. 🌐

Key components

The following key elements are inherent in an electromagnetic flowmeter for correct measurement:

🌐Flow Tube: Directs the fluid through the measurement procedure; made of non-magnetic materials like Teflon or stainless steel.

🚀Excitation Coil: Around the flow tube and produces the magnetic field that interacts with the fluid.

⚡Sensing Electrodes/Flow Sensor: are placed into the flow tube and sense the voltage generated across the fluid that is proportional to the fluid’s velocity.

🔌Signal Converter: Enhances and modulates the weak electrical impulses from the electrodes to quantifiable outputs.

📊 Transmitter/Display Unit: With added capabilities like data recording and communication interfaces, the unit grabs the modified pulses and outputs vital data, especially flow rate.

🔗Grounding Electrodes: minimize noise and act as voltage reference points, establishing a good electrical connection with the fluid.

These parts make up an electromagnetic flowmeter’s main elements, alongside the power supply. The transmitter handles data, the flow sensor determines fluid velocity, and the power source powers the meter with electricity. Collectively, they facilitate accurate and credible measurements of fluid flow.

You may be wondering 🤔 how these flowmeters operate at this point. Enter its enticing operational/working concept now.

Working principle

Faraday’s Law of electromagnetic induction is used by electromagnetic/magnetic flowmeters. When conductive liquid passes through the magnetic field produced by the flowmeter, voltage is produced. It is possible to calculate the flow rate precisely by gauging this voltage. It appears to be magic occurring within those lines! ✨

Here is a brief description of how they operate:

💡 Magnetic Field Generation: The excitation coil and the sensing coil, a pair of two coils, produce a magnetic field that encircles the pipe.

💧 The flow of a Conductive Fluid: The pipe is traversed by a conductive fluid.

⚡️ Induced Voltage: As a fluid passes through a magnetic field, Faraday’s law creates a voltage that is perpendicular to both the field and the direction of flow.

📊 Voltage Detection: In proportion to the fluid’s velocity, the sensor coil picks up the created voltage.

🔢 Calculation of Flow Rate: Using the observed voltage, the meter determines the liquid’s flow rate by taking electromagnetism and fluid dynamics into account.

Electromagnetic/magnetic flowmeters can accurately measure fluid flow thanks to this underlying concept, and a variety of industries employ them.

Advantages

The ease of maintenance of electromagnetic/magnetic flowmeters is one of its most appealing features. They don’t have any moving components to be concerned about, so maintenance is minimal. Farewell to often-needed fixes 🛠️and welcome to continuous operations! Additionally, even in turbulent fluids and low flow rates, their accuracy levels are exceptional, ensuring precise readings in even the most demanding situations. 🔍

Electromagnetic/magnetic flowmeters are now essential tools in sectors where reliable operations and limited maintenance requirements are critical. They offer a wide range of advantages, including accurate flow monitoring, simple installation, and savings in the long run. 🌈 Additionally, they work well with a variety of conducting liquids, including ones with corrosive characteristics or high solid contents. 💪🌊

Understanding electromagnetic/magnetic flowmeters is crucial for any company that depends on fluid flow management. 🚀 Follow along till we investigate numerous applications in the real world.

Real-world applications

Electromagnetic/magnetic flowmeters are used in various industries and applications, including:

🌊Water treatment,

Chemical processing🔬,

🍹Food and beverage production,

Mining⛏️, and

💊 Pharmaceutical production.

Examples of those real-world applications

Electromagnetic/magnetic flowmeters are adaptable marvels that may be used in a wide range of fields and applications:

💧Water treatment: These meters assess the flow of water in treatment facilities (at different phases of sedimentation, filtration, and disinfection), guaranteeing effective resource management and conserving water.

🧪Chemical processing🔬: During manufacturing operations (mixing, blending, reaction), flowmeters reliably monitor chemical flow for a variety of substances, including acids and solvents. This assures exact control.

🍹Food and beverage production🍻: During bottling and canning, flowmeters give accurate liquid flow measurements, ensuring product quality, uniformity, and flavor perfection in every container.

⛏️Mining: These meters examine the flow of slurries (water, crushed minerals, and ores), which optimizes resource extraction and usage.

💊Manufacturing of Medications: Pharmaceutical companies need the finest possible degree of precision. These flowmeters maintain excellent pharmaceutical standards by rigorously ensuring dose accuracy for every run of drug manufacture.

Flowmeters demonstrate their value 💪 in an array of segments, including ⛏️mining operations, water 🌊 quality assurance, chemical 🧪 optimization, 🍻beverage perfection, and pharmaceutical 💊 accuracy.

Installation and maintenance

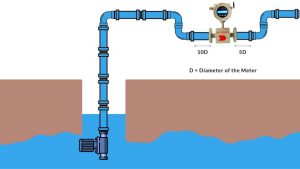

These flowmeters can be mounted horizontally or vertically and are normally positioned in a section of a straight line that is unobstructed by any objects. However, a U-bend is ideal for these flowmeters (as seen in the remaining photographs). As there are no mechanical components that need oiling or alignment, maintenance is little.

📋Pre-Installation Checklist:

-

Examine the instructions and standards provided by the manufacturer.

-

Decide on a suitable installation site.

-

Verify that the electrical wiring and grounding are correct.

-

Take into account the suitability of pipe dimensions and material.

-

Obtain the required licenses and permits.

🚧 Installation Process:

-

Depressurize the conduit and stop the flow before installing it.

-

Attach the flowmeter to a segment of straight pipe.

-

Correctly align the flowmeter with the flow.

-

Install the flowmeter firmly using the proper fittings.

-

Assemble the wiring and cables as per the manual’s directions.

-

Visually check the area for any leaks or anomalies.

🔍 Verification and Testing:

-

Examine every component visually.

-

Evaluate the flowmeter’s performance.

-

Verify that all electrical connections are secure.

-

Check the flow sensor’s positioning and orientation.

-

Verify that the grounding is solid and reliable.

🛠️Regular maintenance:

-

Check the flowmeter for physical damage.

-

Keep the electrodes and flow sensor

-

Inspect electrical connections for looseness or rusting.

-

Check the wiring and cable

-

Keep an eye out for any indications of unusual performance.

⏳ Calibration and Re-Calibration:

These meters have a high degree of precision and an error percentage that’s under 1%. Since variations in fluid viscosity, density, or electrical conductivity might alter the results, periodic calibration may be necessary to make certain that the calibration curve remains truthful.

-

When calibrating, go according to the manufacturer’s instructions.

-

Conduct routine calibrations to keep precision.

-

If necessary, take into account external calibrating services.

-

Save calibration information for later use.

🧪Troubleshooting and Support:

-

Become familiar with troubleshooting techniques.

-

Consult the user guide or get in touch with technical assistance.

-

Quickly address any problems to reduce downtime.

-

Stay current with firmware and software updates.

⚙️Your electromagnetic/magnetic flowmeter will operate accurately and dependably if it is installed, maintained regularly, and calibrated on schedule.

Choosing the right EMF for your business needs

Together, we’ll develop the knowledge required to select the ideal electromagnetic/magnetic flowmeter for the needs of your business. 💪 Consider the following factors when selecting a flowmeter:

💧 Fluid type: Confirm appropriateness for the fluid being measured.

⚡ Conductivity: Verify the requisite conductivity minimum.

🌊 Flow rate range: Determine the expected flow rate.

📏 Pipe size: Verify conformance with the conduit size.

🎯 Accuracy needs: Determine the required accuracy level.

💰 Price: Compare it to your spending limit.

🔩 Installation: Consider how simple it is to install.

🔧 Maintenance costs: Costs associated with maintenance should be factored in.

You may make a well-informed selection and get the best meter for your application by taking these aspects into account.

U bend for Electromagnetic Flowmeter showing flow animation

Conclusion: Investing in EMF

Electromagnetic/magnetic flowmeters are used in businesses wherein 🌊 fluid measurement, as well as surveillance, are crucial. They provide a high-accuracy, effortless to maintain option that keeps your business operations going seamlessly. 💪

It’s essential to comprehend their 🔧 installation, maintenance, and important parts. Each component, including the flow tube, coils, electrodes, and the transmitting device, is essential. 💡 They guarantee accurate fluid flow measurement for conductive liquids by following Faraday’s principle of electromagnetic induction. 📈 These flowmeters provide process optimization and product quality enhancement.

Please leave any ❓ queries or remarks you may have regarding electromagnetic/magnetic flowmeters in the comments section. 👇 We’re excited to hear from you and here to assist! 👇